|

Welding Equipment

The weld equipment that we build is focused on maximizing production, while reducing errors and increasing safety.

Below are a some examples that we have designed and built. |

|

Spot Welder

Description:

Manual load/unload, 4-out, part specific, semi-automatic DC spot welder

Build Time:

17 weeks

|

Part Description:

Steel automotive center reinforcement assemblies (right hand and left hand)

| |

|

Robotic Spot Welder

Description:

Manual load/unload, 1-out, part specific, robotic spot welder

Build Time:

16 weeks

|

Part Description:

Automotive front row back frame

| |

|

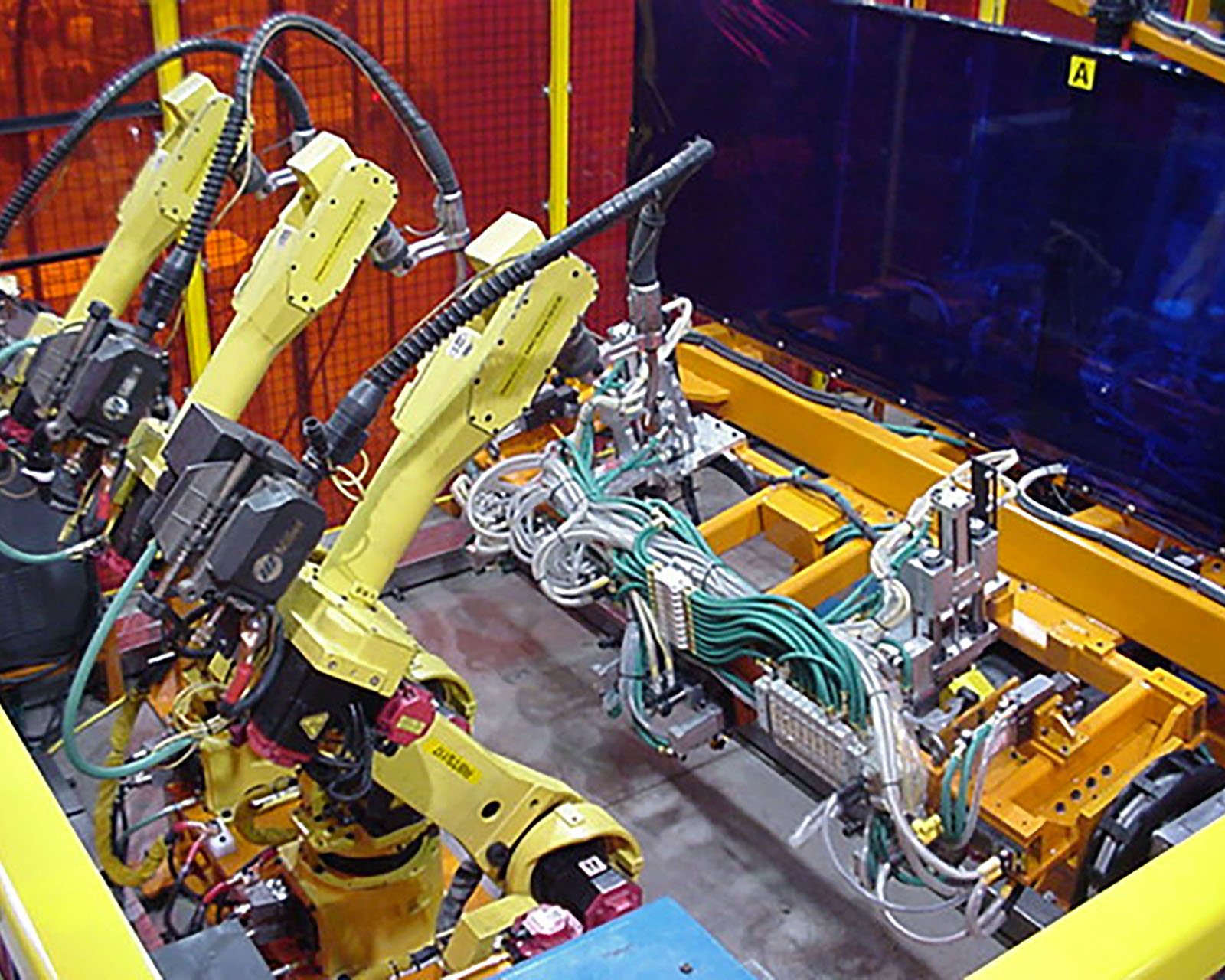

3-Robot MIG Welder Refurbish/Repurpose & New Fixtures

Description:

- (2) Manual load/unload, 1-out, part specific weld fixtures.

- Refurbish and repurpose existing 3-robot MIG welder.

Build Time:

17 weeks

| Part Description:

Automotive front bumper assembly

| |

|

Robotic MIG Welder & Box Turner

Description:

Semi-automatic box turner & robotic MIG welder, including hard guarding, weld screen, safety door, and light curtain. The fixture rotates 180 degrees for welding access and can accomodate different part sizes.

Build Time:

18 weeks

|

Part Description:

Tubular frame, wheel wells, front panel, back panel, roof panel, side panels, & door panel. Largest part size: 102" x 82" x 67".

Approximate Part Assembly Weight:

500 lbs

| |

|

|

|

|

|

|